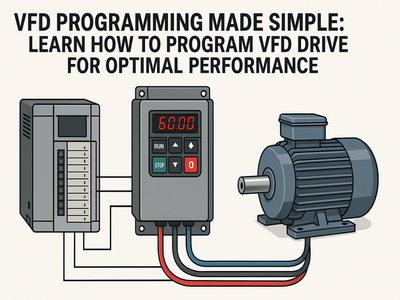

VFD programming is essential to effective and optimized motor control and energy efficiency in the industrial automation world. VFD, full form Variable Frequency Drive, is a parameter that helps to control the motor speed and torque from an electric component drive by controlling the frequency and voltage supplied to the electric motor. In this detailed guide, you will learn about the VFD working principle, the VFD drive working, & VFD integration with PLC.

What is VFD in Electrical Systems?

A Variable Frequency Drive (VFD) is electronic conveying equipment that varies frequency and voltage which controls an electric motor. VFD stands for Variable Frequency Drive, which is a device that provides precise control over the operations of a motor, which requires energy savings and improved performance. VFDs permit less aggressive motor work and lower wear and tear by converting fixed-frequency AC power into variable-frequency AC power.

Understanding VFD Working Principle

The basic working principle of VFD is to convert the received AC power into DC and then convert it back to a controlled AC output by means of an inverter. It then enables the VFD to effectively control motor speed/torque running. Variants include the VFD controller, VFD electric parts, and VFD inverter. This consists of a rectifier that converts the AC to DC, a DC link that smoothens the output characterized by the fluctuation of output voltage, and an inverter that converts the DC back to variable AC. Such flexibility enables fine-tuning of motor control.

Types of VFD and Their Applications

There are various types of VFDs based on the motor type and control method. Common VFD applications include:

- HVAC systems for temperature control and ventilation.

- Conveyor belts in manufacturing units for consistent speed control.

- Water pumps are used in industrial setups for flow rate management.

- Elevators and escalators for smooth and safe operation.

- Renewable energy systems, like wind turbines, for optimize power generation.

Each type of VFD is designed to handle different power capacities and motor specifications, ensuring compatibility with diverse industrial applications.

Basics of VFD Programming

VFD programming basics involve setting parameters to control motor speed, acceleration, deceleration, and torque. By accessing the VFD programming manual, users can configure settings for optimal performance. Programming VFD drives requires understanding the interface, setting the control modes, and fine-tuning the parameters for efficiency. Key aspects include:

- Frequency and voltage control: Adjusting the output frequency to match the motor’s operational requirements.

- Acceleration and deceleration ramps: Controlling the speed of starting and stopping to prevent mechanical stress.

- Torque control: Managing torque for different load conditions.

VFD PLC Programming: A Step-by-Step Guide

VFD programming with PLC enables the VFD to communicate and interface freely with the Programmable Logic Controller (PLC). And this is how you can do it:

- VFD Wallart: Build the VFD physical connection for VFD and PLC using proper communication protocols. Modbus, Profibus, or Ethernet/IP.

- Step 1: Parameter Configuration. Go to the VFD controller and configure the parameters such as the Frequency, voltage, and current limits

- Control Logic: Create the control logic in the PLC software in order to run the VFD.

- Data Exchange: Real-time monitoring of speed, torque, and fault signals

- Testing and Calibration: After proper installation and wiring inspection, run tests to check if the VFD drive is working properly and troubleshoot any error codes.

Lenze VFD Programming and Training

Lenze VFD programming is popular in industrial automation because of its RF and VFD-related features. This training will develop the skills of engineers who plan to work on VFDs, which particularly includes Lenze VFD programming training. It includes training on practical aspects such as motor tuning, fault diagnostics, and advanced control methods. Hence, it is important to know these, as they help in the management of larger applications and system stability.

Troubleshooting and Maintenance

Common Problems like Overheating, Overcurrent Faults, and Communication Errors become clear by understanding the VFD drive working principle. VFD function can be improved and system life extended through regular maintenance and firmware upgrades. Essential troubleshooting steps include:

- Checking wiring and connections.

- Analyzing fault codes and error logs.

- Adjusting parameter settings for specific applications.

- Inspecting cooling systems and ventilation.

Future Trends in VFD Programming

With advancements in IoT and AI, VFD programming in PLC is evolving. Smart VFDs can now monitor energy consumption, predict failures, and provide remote diagnostics, improving overall system efficiency. Emerging technologies include:

- Cloud-based VFD management for remote access and control.

- Predictive maintenance algorithms for identifying potential failures.

- Energy optimization features for reducing power consumption.

Conclusion

Learning VFD programming enables an industrial setup to optimize the motor control and achieve energy efficiency. VFDs are more complex than they appear to be at first glance; however, using the knowledge from the VFD programming manual and VFD PLC programming, as well as programming VFD drives, you will be able to optimize the system for increased performance while minimizing downtime. Proficiency in basics and advanced techniques will be key to your success in the world of industrial automation, whether or not you’re programming Lenze VFDs or other.

Looking to enhance your industrial automation with expert VFD programming solutions? Aknitech is here to help! Our team specializes in VFD programming in PLC, Lenze VFD programming, and customized solutions for your business. Visit us at aknitech.in to learn more and elevate your automation game today.