In the rapidly evolving landscape of industrial automation, PLC electrical panels serve as the backbone for controlling machinery and processes. These panels house Programmable Logic Controllers (PLCs), the brains behind automated systems, ensuring seamless and efficient operations across manufacturing units, power plants, and various industries.

Aknitech Automation, a leader in industrial automation solutions, specializes in designing and manufacturing high-quality PLC electrical panels tailored to meet diverse industry needs.

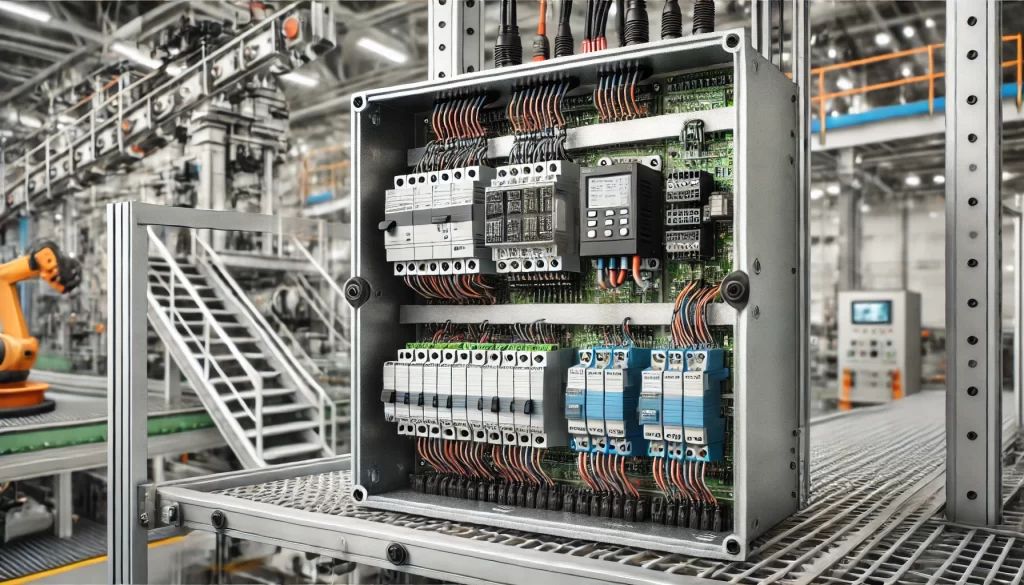

What is a PLC Electrical Panel?

A PLC electrical panel is an enclosure that contains and organizes PLC hardware, wiring, input/output (I/O) modules, power supplies, communication devices, and other essential components required for industrial automation. These panels protect sensitive electronic components from environmental factors while facilitating easy monitoring, troubleshooting, and expansion.

Key Components of a PLC Electrical Panel

- Programmable Logic Controller (PLC):

- The PLC is the core component responsible for executing control logic programmed to automate processes.

- It processes input signals from sensors and field devices and triggers output actions like starting motors, opening valves, or controlling lights.

- Power Supply:

- Converts incoming AC power to the necessary DC voltage required to operate the PLC and other panel components.

- Input and Output (I/O) Modules:

- These modules receive signals from field devices (inputs) and send control commands to actuators (outputs).

- Communication Modules:

- Facilitate data exchange between the PLC, Human-Machine Interfaces (HMIs), and other systems, allowing remote monitoring and control.

- Circuit Breakers and Fuses:

- Protect the panel and connected devices from electrical overloads and short circuits.

- Terminal Blocks:

- Provide organized connection points for field wiring, ensuring structured and safe cable management.

- Cooling and Ventilation:

- Essential for preventing overheating and ensuring the longevity of panel components.

Benefits of PLC Electrical Panels

- Efficiency and Accuracy: Automates complex processes, reducing human error and increasing productivity.

- Flexibility: Easily reprogrammed to adapt to new processes or equipment, providing scalability.

- Remote Monitoring: Allows operators to control and monitor equipment from remote locations, minimizing downtime.

- Cost-Effective: Reduces operational costs by optimizing energy usage and process efficiency.

- Safety: Enhances workplace safety by automating hazardous tasks.

Applications of PLC Electrical Panels

- Manufacturing: Control assembly lines, robotic arms, and conveyor systems.

- Energy Sector: Manage power distribution, substations, and renewable energy systems.

- Water Treatment Plants: Automate pumps, valves, and filtration systems.

- Food and Beverage: Control batch processing, packaging, and quality inspection.

- Building Automation: Regulate HVAC systems, lighting, and security.

How to Design a PLC Electrical Panel

- Understand the Requirements:

- Assess the automation needs, number of I/O devices, and environmental conditions.

- Select the Right PLC:

- Choose a PLC that can handle the required I/O points and communication protocols.

- Panel Layout:

- Ensure logical placement of components to facilitate maintenance and future expansion.

- Wiring and Labeling:

- Use color-coded and labeled wires to simplify troubleshooting.

- Testing and Validation:

- Perform rigorous testing to ensure the panel operates correctly under different scenarios.

Conclusion

PLC electrical panels play a critical role in driving industrial automation by providing a centralized control system that enhances productivity, safety, and efficiency. Aknitech Automation continues to lead the way in delivering cutting-edge PLC panel solutions, ensuring industries stay competitive and future-ready. As industries evolve, the demand for reliable and scalable PLC panels will only grow, making them indispensable for modern automation solutions.