Supervisory Control and Data Acquisition (SCADA) software has become a cornerstone of industrial automation. By offering real-time data acquisition, monitoring, and control, SCADA systems enable industries to enhance efficiency, safety, and productivity. Whether it’s in manufacturing, power generation, water management, or building automation, SCADA software plays a crucial role in ensuring operations run smoothly, with minimal downtime and optimized resource utilization.

In this blog, we’ll explore what SCADA software is, its core functionalities, benefits, common applications, and future trends shaping its evolution.

1. What is SCADA Software?

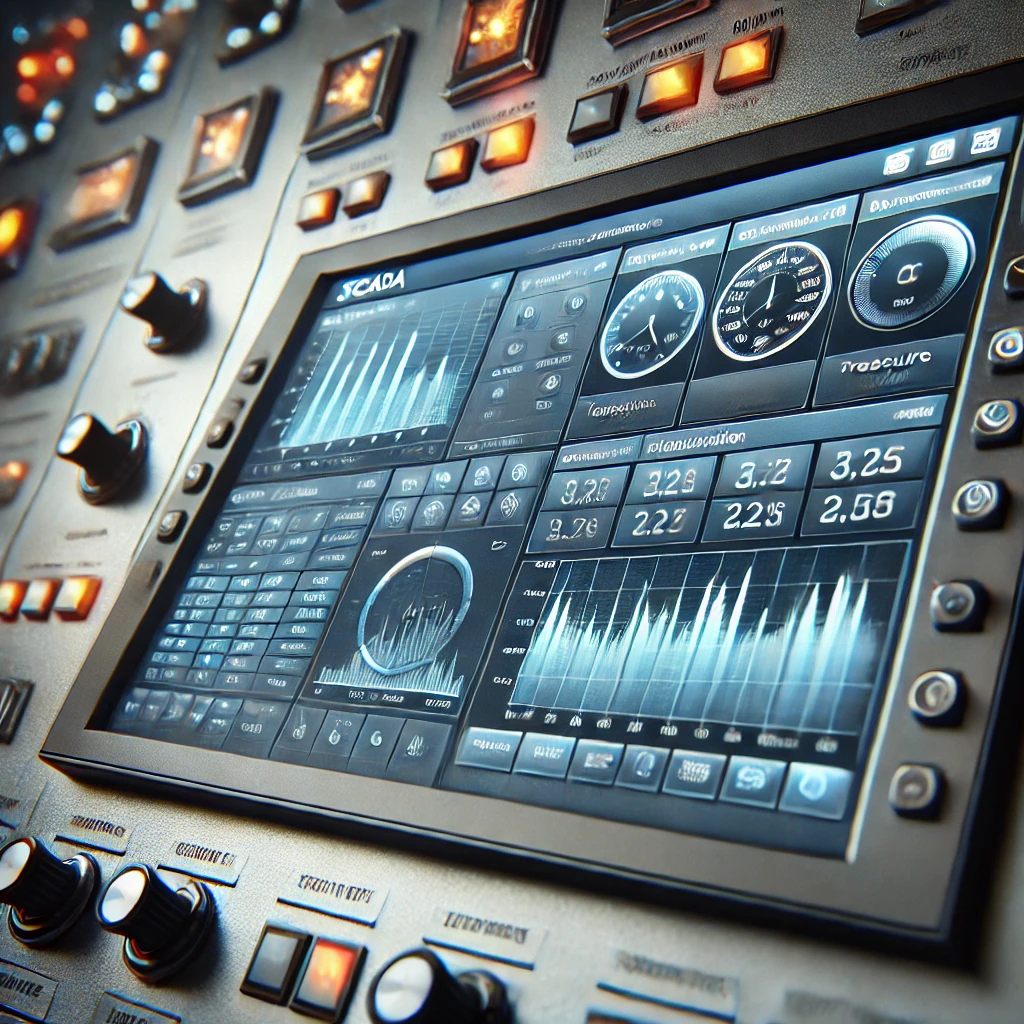

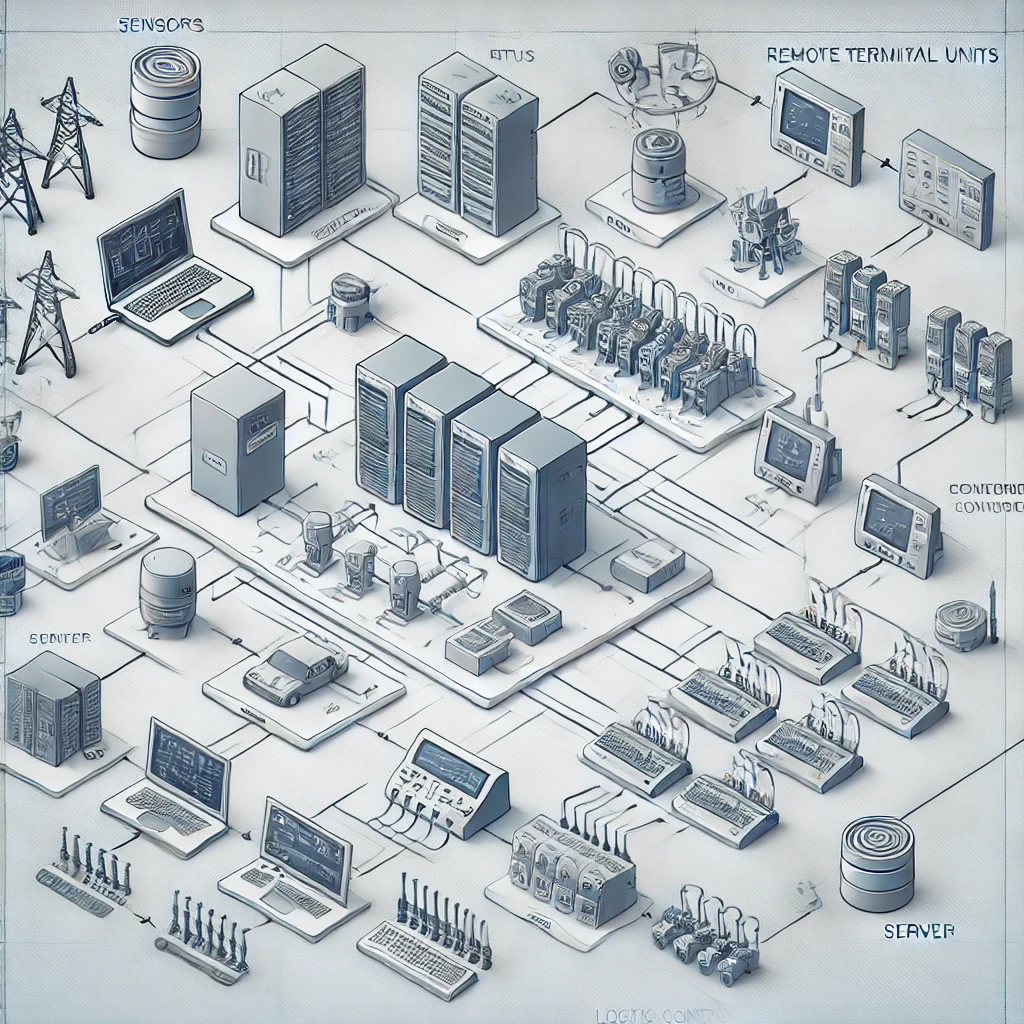

SCADA software is a centralized system designed to monitor, gather, and analyze real-time data from equipment and processes within an industrial environment. Through a combination of hardware and software components, SCADA systems provide operators with insights into the status and performance of machinery, enabling remote control and troubleshooting.

Key Components of SCADA Systems:

- Human-Machine Interface (HMI): The graphical interface through which operators interact with the system.

- Supervisory Computer Systems: The central computers that process data from sensors and control devices.

- Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs): Devices that gather data from sensors and equipment, sending it to the supervisory system.

- Communication Infrastructure: Networks and protocols enabling data transfer between components, including wireless and Ethernet connections.

2. Core Functionalities of SCADA Software

SCADA software provides various functionalities that empower industrial facilities to maintain control and enhance productivity. Here’s a look at some of the core features:

- Data Acquisition and Monitoring: SCADA systems collect data from sensors, tracking variables like temperature, pressure, flow rates, and more. This data is then displayed on the HMI for real-time monitoring.

- Control: Operators can remotely control equipment, such as turning devices on or off, adjusting parameters, or resetting faults, which is particularly useful for large or hazardous areas.

- Alarms and Notifications: SCADA software triggers alarms when values deviate from pre-set limits, allowing for quick response to prevent malfunctions or accidents.

- Data Logging and Analysis: SCADA systems store historical data, which can be used for trend analysis, performance evaluation, and troubleshooting.

- Reporting: Detailed reports are generated on various metrics, providing insights into system performance, equipment efficiency, and energy usage.

3. Benefits of SCADA Software in Industrial Automation

SCADA software offers a variety of advantages that contribute to operational efficiency, cost savings, and safety.

A. Enhanced Operational Efficiency

With real-time data monitoring, SCADA enables quick responses to issues, optimizing productivity by reducing downtime. Operators can adjust settings and parameters based on the actual conditions of the machinery, maximizing output.

B. Improved Decision-Making

SCADA software provides actionable insights through data collection and analysis, helping managers make data-driven decisions. By studying trends and historical data, operators can fine-tune operations for better efficiency.

C. Reduced Downtime and Maintenance Costs

SCADA systems support predictive maintenance by continuously monitoring equipment health. This proactive approach allows for scheduled maintenance, preventing unexpected failures and saving on costly repairs.

D. Increased Safety

SCADA software monitors critical parameters and alerts operators of any abnormalities. For industries handling hazardous materials or processes, these alarms are vital for ensuring safe operations.

E. Remote Accessibility

Operators can access SCADA systems remotely, which is valuable in distributed facilities. This feature allows for remote troubleshooting and control, reducing the need for on-site presence in hazardous or remote locations.

4. Applications of SCADA Software Across Industries

SCADA systems are used in various industries to improve productivity, enhance safety, and reduce costs. Here are a few key application areas:

A. Manufacturing

In manufacturing, SCADA software monitors production lines, controls machinery, and tracks quality. It enables manufacturers to optimize production efficiency, identify bottlenecks, and maintain consistent product quality.

B. Power and Utilities

Power plants use SCADA to monitor and control the distribution of electricity, water, and gas. By detecting and responding to power faults or fluctuations, SCADA ensures a stable supply and improves grid reliability.

C. Oil and Gas

In the oil and gas industry, SCADA systems oversee drilling, production, and pipeline monitoring. SCADA’s real-time data collection helps operators monitor pressure, detect leaks, and ensure environmental compliance.

D. Water and Wastewater Management

SCADA software is vital for managing water treatment facilities, tracking water quality, and ensuring the distribution of clean water. It helps utilities meet regulatory standards and manage resources efficiently.

E. Building Automation

SCADA systems are also used in smart buildings for monitoring HVAC systems, lighting, and security. They help in managing energy consumption, reducing operational costs, and creating comfortable and safe environments.

5. SCADA System Architecture: Centralized vs. Distributed

SCADA architectures can be categorized into centralized and distributed systems:

- Centralized SCADA: A single supervisory system collects data from multiple remote units, often used in smaller facilities or operations.

- Distributed SCADA: Used in large-scale applications, distributed SCADA systems have multiple supervisory computers managing data, making them ideal for geographically dispersed operations like utilities and pipelines.

6. SCADA Communication Protocols

SCADA systems rely on various communication protocols to ensure efficient data exchange between components. Some popular protocols include:

- Modbus: A widely used protocol, Modbus is simple and ideal for communication between PLCs and other equipment.

- DNP3 (Distributed Network Protocol 3): Common in electric power systems, DNP3 is known for its reliability in complex, large networks.

- OPC UA (Open Platform Communications Unified Architecture): An open protocol that facilitates secure data transfer, OPC UA is increasingly used for its interoperability with IoT and Industry 4.0 technologies.

7. SCADA Software Trends and Future Developments

The evolution of SCADA software is influenced by Industry 4.0, the Internet of Things (IoT), and cloud computing. Here are a few trends shaping the future of SCADA:

A. Integration with IoT and Edge Computing

SCADA systems are increasingly integrating with IoT devices, enabling advanced data collection and analytics. With edge computing, data processing occurs closer to the source, reducing latency and improving response times.

B. Cloud-Based SCADA Solutions

Cloud-based SCADA offers scalability, lower infrastructure costs, and easy access to data. Operators can access real-time data from anywhere, improving flexibility in distributed environments.

C. Artificial Intelligence and Machine Learning

AI and ML algorithms are being integrated into SCADA systems to enable predictive analytics, anomaly detection, and intelligent decision-making. These capabilities enhance predictive maintenance and optimize system performance.

D. Enhanced Cybersecurity

As SCADA systems become more connected, cybersecurity is a growing concern. SCADA vendors are implementing multi-layered security measures, including encryption, firewalls, and role-based access control, to protect against cyber threats.

E. Mobile Accessibility

Modern SCADA software offers mobile accessibility, allowing operators to monitor and control systems through smartphones and tablets. This flexibility enhances productivity and enables faster responses to issues.

Conclusion

SCADA software is essential for industries looking to improve efficiency, safety, and data-driven decision-making. By enabling real-time monitoring and control, SCADA systems help optimize operations, reduce downtime, and ensure compliance with regulatory standards. As new technologies like IoT, cloud computing, and AI continue to influence the industrial landscape, SCADA software will evolve to offer even more powerful capabilities, transforming industrial automation for the future.

For industries seeking to modernize their operations and remain competitive, investing in a robust SCADA solution is a critical step toward a more efficient and resilient future.