Redeveloping process logic is becoming essential as industries seek higher efficiency, adaptability, and quality. Process logic lies at the core of automated industrial operations, acting as a decision-making framework for machines, devices, and production lines. As technological advancements, market demands, and operational goals evolve, outdated process logic hinders productivity, reduces adaptability, and increases costs. This article delves into why process logic redevelopment is critical, detailing the benefits, approaches, challenges, and real-world applications.

1. Introduction to Process Logic in Industrial Automation

Process logic in automation serves as the structured set of instructions that define how machinery, devices, and systems operate. Primarily found in Programmable Logic Controllers (PLCs), process logic drives actions based on sensor inputs, operator commands, and pre-defined conditions, such as temperature thresholds or motion detection. The design of process logic significantly impacts workflow, efficiency, and output quality. However, as industry standards evolve, maintaining outdated or inefficient logic negatively impacts productivity, increasing downtime and energy usage.

Importance of Process Logic

Process logic is crucial for the seamless functioning of production lines, allowing for automatic decisions without operator intervention. For instance, it dictates responses in emergencies (like machinery stopping upon detecting a malfunction) or optimizes equipment usage to reduce energy costs. However, as new technology becomes available, keeping outdated logic can impede these benefits.

When is Redevelopment Necessary?

Redevelopment often becomes necessary when:

- System Upgrades: New machinery may require compatibility adjustments.

- Operational Goals Shift: Changes in goals like energy efficiency or production speed may call for adjustments.

- Technological Integration: Incorporating IoT and advanced analytics needs logic that can handle real-time data.

2. The Benefits of Redeveloping Process Logic

Redeveloping process logic offers multiple benefits, directly impacting efficiency, productivity, and cost-effectiveness. The major advantages include enhanced precision, improved scalability, and energy efficiency.

A. Enhanced Precision and Consistency

Upgraded logic minimizes human error and ensures higher consistency across production batches. With modern analytics integrated into the process logic, quality deviations can be detected and corrected immediately.

B. Faster Response Times

When logic is updated to handle real-time conditions, response times significantly improve. For instance, modern logic reduces the reaction time of safety systems, allowing immediate shutdowns upon detecting system malfunctions, thus preventing potential damage and reducing downtime.

C. Improved Scalability and Flexibility

As businesses expand, production systems must keep pace. Redeveloping logic enables systems to scale without slowing production or reducing quality. It allows more flexibility in adjusting to changing demands.

D. Energy Efficiency and Sustainability

Modernized process logic can incorporate real-time monitoring to optimize energy consumption, reducing costs and environmental impact. Enhanced logic can identify inefficiencies, automatically adjusting settings to maintain optimal energy usage.

E. Streamlined Human-Machine Interaction

Updated logic facilitates better interfaces, allowing operators to interact more intuitively with the system. With clear dashboards and actionable data, operators can troubleshoot, make adjustments, and optimize production flow efficiently.

3. Indicators for Redeveloping Process Logic

How do you know it’s time to redevelop process logic? Key indicators include frequent downtimes, output quality issues, integration challenges, and an inability to meet evolving operational goals.

A. Frequent Downtime

If production systems are frequently down due to unforeseen issues or outdated automation responses, the logic needs a thorough review.

B. Inconsistent Output Quality

When variations in product quality occur despite stable raw material supplies, outdated logic might be the culprit. Enhanced process logic ensures greater uniformity across production batches.

C. Inflexibility in Production

As demand shifts, it’s essential for production to adapt accordingly. Rigid logic structures make quick adjustments difficult, underscoring the need for redevelopment.

D. Compatibility with New Systems

New machinery or devices may not integrate well with older systems due to compatibility issues, necessitating redevelopment to ensure seamless functionality.

4. How Redeveloped Process Logic Drives Efficiency

A well-planned redevelopment of process logic enhances efficiency by optimizing control, data integration, and resource usage. The following sections outline the efficiency gains in various operational aspects.

A. Adaptive Control and Real-Time Data Integration

Incorporating real-time data enables rapid adaptability to changing conditions. For example, by analyzing sensor data, redeveloped logic can make real-time decisions, adjusting speed, pressure, or temperature to maintain optimal production levels.

B. Workflow Synchronization

Improved synchronization helps streamline operations, reducing bottlenecks and ensuring components are where they need to be, exactly when they’re needed. Synchronization not only increases efficiency but also minimizes the risk of production halts due to misalignment between different stages.

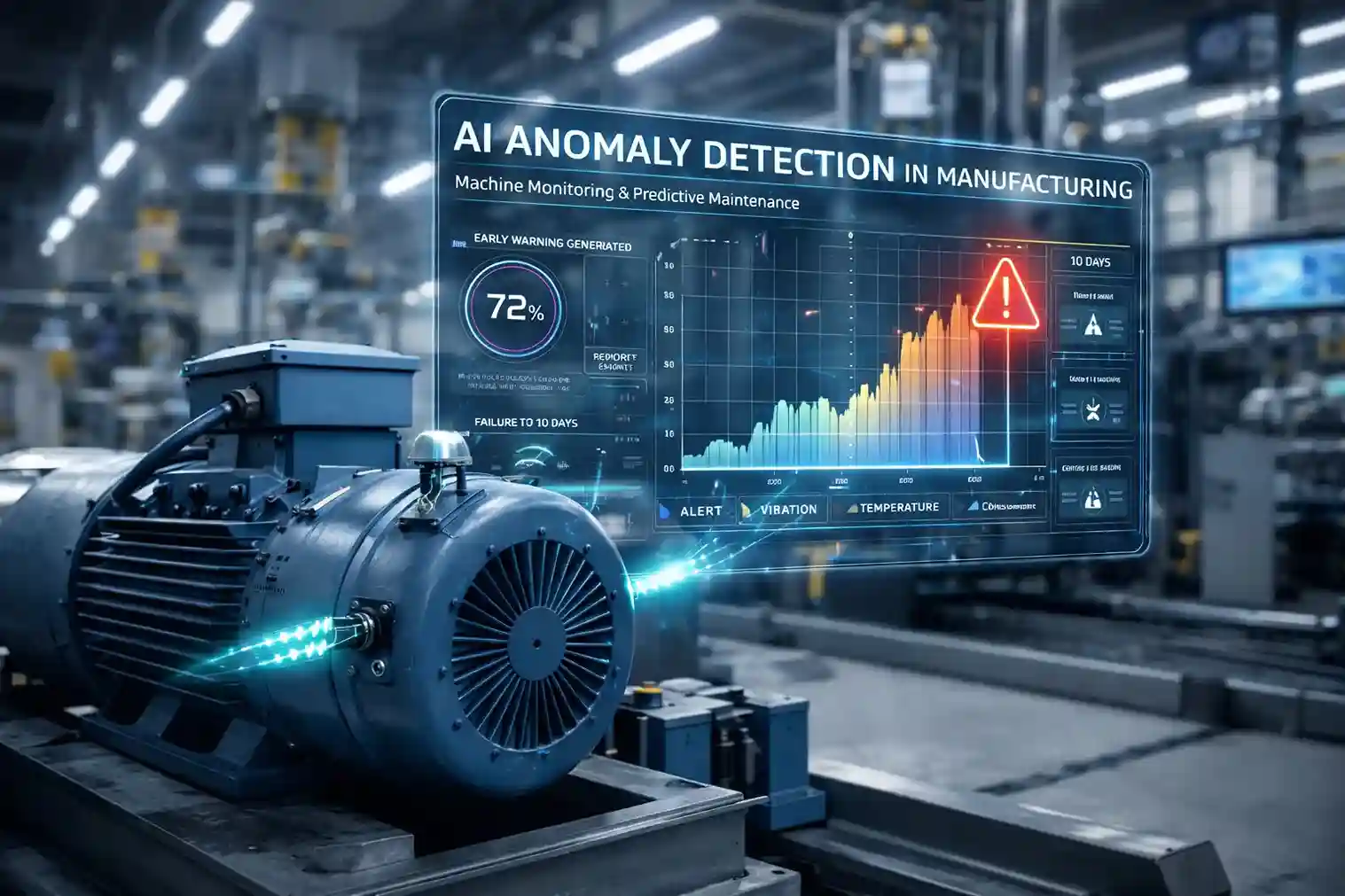

C. Predictive Maintenance and Reduced Downtime

Modernized logic can incorporate predictive maintenance by analyzing data patterns, like machinery vibration or heat levels, to identify potential malfunctions. This minimizes downtime by enabling maintenance to occur before issues escalate, enhancing overall equipment effectiveness (OEE).

D. Optimized Resource Allocation

Process logic that accounts for resource use — such as water, electricity, or raw materials — reduces waste. Optimized logic ensures resources are used precisely as needed, enhancing sustainability and cutting costs.

E. Enhanced Human-Machine Collaboration

Intuitive control panels and responsive systems empower operators, allowing for smoother interactions and quicker troubleshooting, which streamlines production flow and improves job satisfaction.

5. Steps for Redeveloping Process Logic

Redevelopment is a multi-step process requiring careful planning and execution. Below is an outline of best practices for redeveloping process logic:

Step 1: Conduct a Thorough Analysis

Begin by assessing the existing logic, identifying bottlenecks, and understanding limitations. Operator feedback and performance data are essential for determining areas needing improvement.

Step 2: Define Redevelopment Objectives

Set clear goals, whether it’s increasing speed, lowering energy consumption, or improving compatibility with new devices. Defining these targets helps focus efforts and measure success post-implementation.

Step 3: Integrate Modern Technologies

Utilize technologies like IoT and AI for real-time control, predictive maintenance, and data analytics. IoT sensors allow systems to receive real-time input from across the production line, enabling adaptive responses based on live data.

Step 4: Test in Simulated Environments

Before implementing new logic, test it in a controlled setting to identify potential issues. Simulation helps identify problems before they impact production.

Step 5: Deploy in Stages and Train Operators

Implement the redeveloped logic incrementally to manage risks and minimize downtime. Training operators on the new logic ensures a smooth transition, allowing them to leverage the system’s full capabilities.

6. Real-World Applications and Success Stories

Industries that have successfully redeveloped process logic include automotive, food processing, and pharmaceuticals, where precision, consistency, and regulatory compliance are crucial.

Automotive Manufacturing

Automotive plants use redeveloped process logic to enable just-in-time production and flexible assembly lines. Updated logic synchronizes workflows, minimizing storage needs and reducing waste.

Food and Beverage Industry

In food processing, real-time quality control and compliance are critical. Updated logic can track temperature, pressure, and sanitation standards, ensuring product safety and reducing wastage.

Pharmaceuticals

Pharmaceutical companies rely on updated logic for precision in dosing, mixing, and packaging. Enhanced process logic enables compliance with strict regulatory standards, ensuring product quality and patient safety.

7. Overcoming Challenges in Redeveloping Process Logic

While redeveloping process logic is beneficial, it is also challenging. Companies often encounter high initial costs, integration issues, and potential downtime.

Cost and Resource Constraints

Redevelopment can be costly, especially when integrating modern technologies or upgrading existing systems. Planning and allocating resources strategically can help mitigate this challenge.

Change Management

Operators and managers accustomed to old systems may resist the change. Providing comprehensive training and emphasizing the long-term benefits is essential for smooth transitions.

Complexity in Integrating Legacy Systems

Legacy systems can be incompatible with modern logic structures. Bridging the gap through gradual upgrades and middleware solutions can ensure a smooth transition.

Mitigating Downtime

Implementing new logic may temporarily halt production. By introducing changes in phases, companies can reduce disruptions and test system performance incrementally.

8. Future Trends in Process Logic Development

Process logic development is rapidly evolving, influenced by technological advancements like AI, IoT, and data analytics. Future trends may include:

- AI-Enhanced Logic: AI can enable machines to learn and improve over time, adapting logic based on historical data patterns.

- Edge Computing: Localized processing through edge computing reduces latency, allowing faster responses and real-time decision-making.

- Increased Connectivity: IoT integration will continue to expand, connecting more devices and systems to enhance automation, monitoring, and control.

- Cybersecurity in Automation: As automation systems become more interconnected, robust security protocols in process logic will be essential to protect against cyber threats.

Conclusion

Redeveloping process logic is essential for organizations aiming to enhance efficiency, productivity, and adaptability in modern industrial settings. Updated logic facilitates adaptive control, predictive maintenance, energy efficiency, and enhanced human-machine interaction. While redevelopment presents challenges, such as high costs and potential downtime, the long-term benefits of increased output quality, reduced waste, and improved operational flexibility justify the investment.

In the fast-paced world of industrial automation, companies that prioritize process logic redevelopment will be better equipped to handle market shifts, integrate emerging technologies, and meet evolving customer demands. By implementing best practices and embracing future trends, organizations can future-proof their operations, ensuring continued competitiveness in an increasingly automated world.