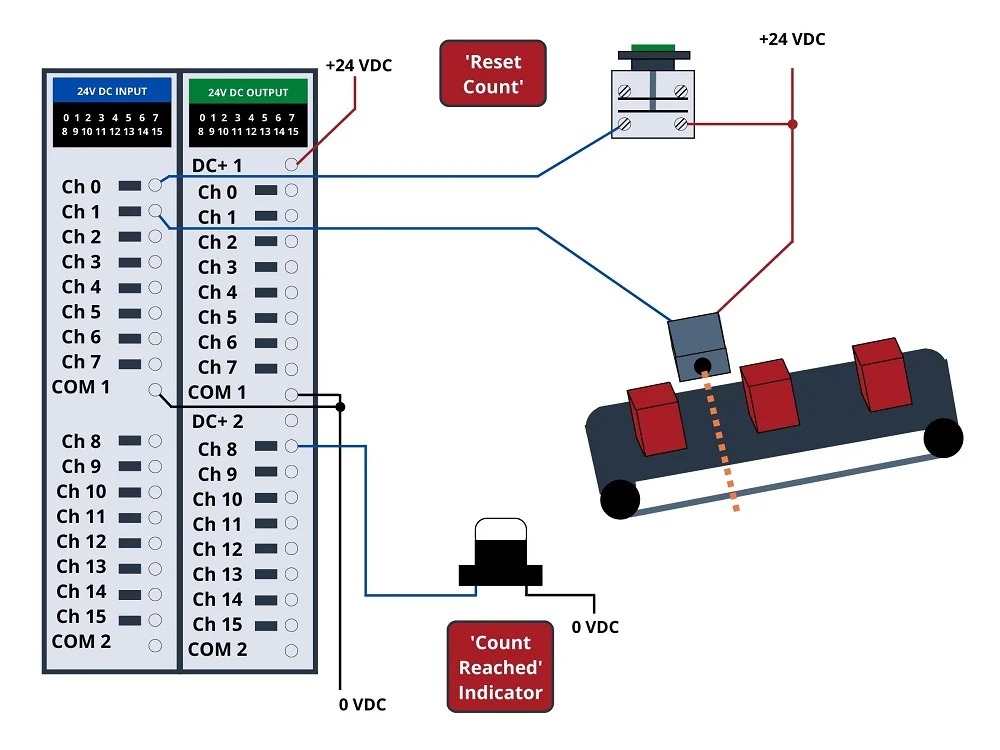

PLC (Programmable Logic Controller) programming forms the backbone of industrial automation. Defined by the IEC 61131-3 standard, there are five main types of PLC programming languages: Ladder Logic, Structured Text, Function Block Diagrams, Sequential Function Charts, and Instruction Lists. Each has unique strengths, weaknesses, and applications that make them suitable for various use cases in manufacturing, process control, and beyond.

Understanding these languages is essential for every PLC programmer, enabling them to choose the right tool for the job, troubleshoot effectively, and deliver efficient solutions. Let’s dive into the top five PLC programming languages and their applications.

1. Ladder Logic (LD)

Overview:

Ladder Logic is the most widely used PLC programming language. Originally modeled after relay-based control systems, it mimics electrical circuit schematics, making it intuitive for electricians and automation professionals.

Advantages:

- Easy to visualize and troubleshoot.

- Modular design simplifies updates and modifications.

- Standardized structure ensures consistency.

Challenges:

- Less intuitive for those with a software background.

- Slower development due to its drag-and-drop nature.

- Limited suitability for complex control processes like PID loops.

Best For:

Sequential Boolean tasks, basic automation processes, and systems requiring frequent maintenance by non-specialists.

2. Structured Text (ST)

Overview:

Structured Text is a high-level text-based language resembling programming languages like C or Python. It offers flexibility and precision for complex automation tasks.

Advantages:

- Intuitive for software developers transitioning to PLC programming.

- Ideal for loops, calculations, and data manipulation.

- Standardized across many PLC platforms.

Challenges:

- Difficult to troubleshoot without a strong programming background.

- Higher error potential due to increased flexibility.

Best For:

Complex applications requiring advanced logic, data processing, or repetitive tasks like FOR loops.

3. Function Block Diagrams (FBD)

Overview:

Function Block Diagrams are highly visual and intuitive, making them excellent for processes like PID control and analog scaling. They are particularly useful in chemical and process industries.

Advantages:

- User-friendly visual editor.

- Ideal for implementing complex control systems on a single sheet.

- Effective for motion control and Add-On Instructions (AOIs).

Challenges:

- Difficult to standardize across projects.

- Can become overwhelming for large-scale implementations.

Best For:

Analog scaling, PID loops, and motion control sequences.

4. Sequential Function Charts (SFC)

Overview:

Sequential Function Charts are designed for step-by-step processes, like those found in chemical batching or sequential manufacturing.

Advantages:

- Mirrors the flow of sequential processes.

- Allows integration with Structured Text for advanced logic.

Challenges:

- Limited to sequential applications.

- Parallel flows can be difficult to implement and troubleshoot.

Best For:

Processes with distinct steps, such as brewing, chemical transformations, or batching operations.

5. Instruction Lists (IL)

Overview:

Instruction Lists provide a text-based approach similar to assembly language. While not as popular, they offer a highly standardized and instruction-focused method for programming.

Advantages:

- Clear instruction flow and explicit variable declarations.

- Highly standardized, ensuring consistency.

Challenges:

- Limited availability on modern PLC platforms.

- Less intuitive compared to other languages.

Best For:

Applications requiring high levels of instruction clarity, especially on platforms that support Instruction Lists.

Can Python Be Used in PLC Programming?

Yes, Python is increasingly being used in PLC programming, especially for advanced machine learning and data analytics applications. Python’s extensive library support and flexibility make it a valuable addition to industrial automation.

Advantages of Python:

- Easy to learn and implement.

- Excellent for data-intensive and machine learning tasks.

- Provides access to advanced libraries unavailable in traditional PLC languages.

Conclusion

The five most popular PLC programming languages—Ladder Logic, Structured Text, Function Block Diagrams, Sequential Function Charts, and Instruction Lists—are foundational for any automation professional. While Ladder Logic remains the industry standard due to its simplicity and widespread adoption, mastering other languages opens new possibilities for handling complex automation challenges.

At the start of your PLC programming journey, focus on Ladder Logic. Once comfortable, expand your skillset to include Structured Text, Function Block Diagrams, and other languages tailored to specific applications. Understanding these languages ensures you’re prepared to tackle any industrial automation project with confidence.