In today’s fast-paced industrial environment, HMI Efficiency is key to achieving optimal performance. One significant component driving this efficiency is Human-Machine Interface (HMI) technology. HMI displays serve as the bridge between operators and machines, enhancing industrial automation across various sectors. This blog explores how HMI displays contribute to HMI Efficiency, offering benefits that are crucial for modern manufacturing.

Understanding HMI in Industrial Automation

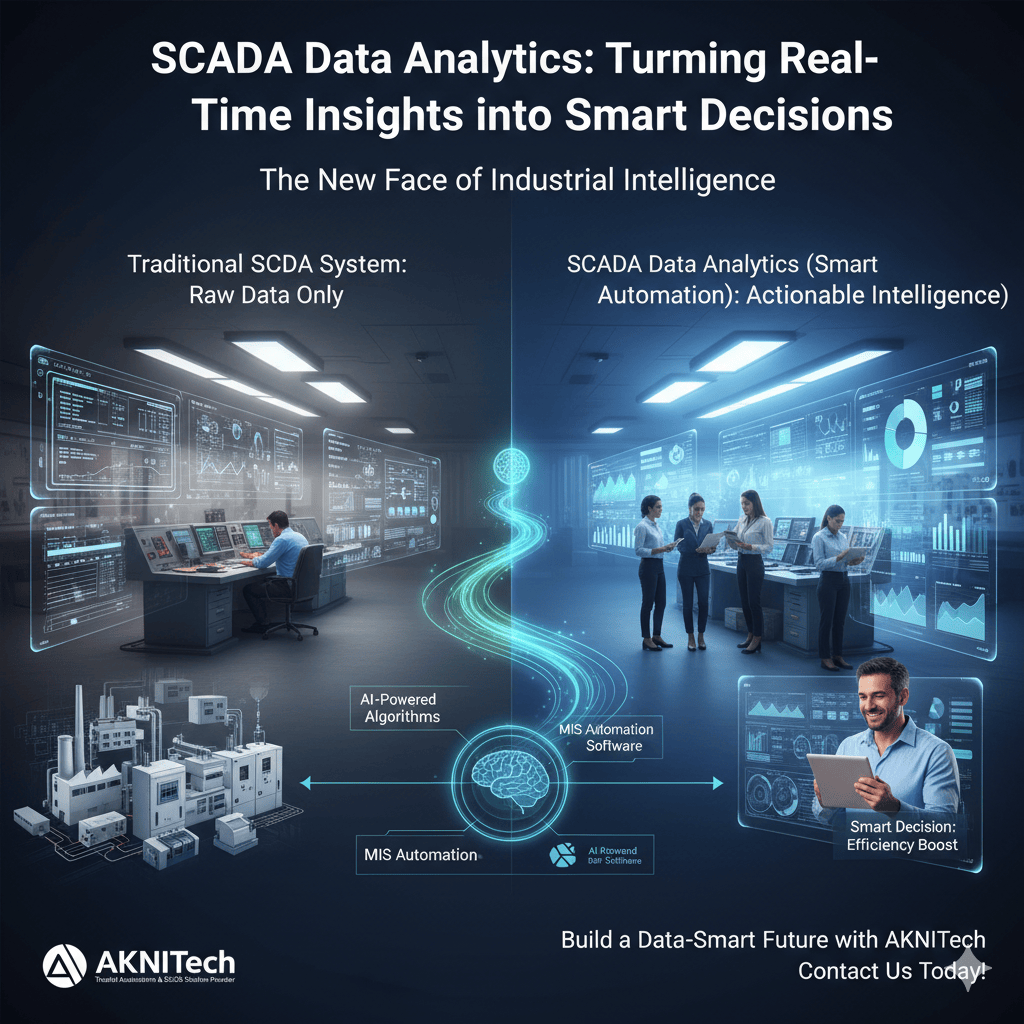

HMI systems allow operators to interact with machines and control processes in real-time. These interfaces provide visual representations of equipment status, production data, and control options. With user-friendly displays, operators can make informed decisions quickly.

In industrial automation, HMI technology plays a vital role. It simplifies complex processes, enabling operators to monitor multiple machines simultaneously. As a result, businesses can achieve higher productivity levels.

Key Benefits of HMI Displays

- Improved Communication HMI displays facilitate better communication between machines and operators. By presenting data in an intuitive format, these systems make it easier for operators to understand equipment status and performance metrics. This clear communication reduces the chances of errors and enhances decision-making processes.

- Real-Time Monitoring With HMI technology, operators can monitor processes in real-time. This feature allows them to identify issues quickly and respond before problems escalate. For instance, if a machine is operating outside its normal parameters, the HMI can alert the operator, enabling immediate corrective action.

- Enhanced Data Analysis HMI systems gather vast amounts of data from various machines. This data can be analyzed to identify trends, optimize processes, and predict maintenance needs. By leveraging this information, businesses can enhance their operational efficiency and reduce downtime.

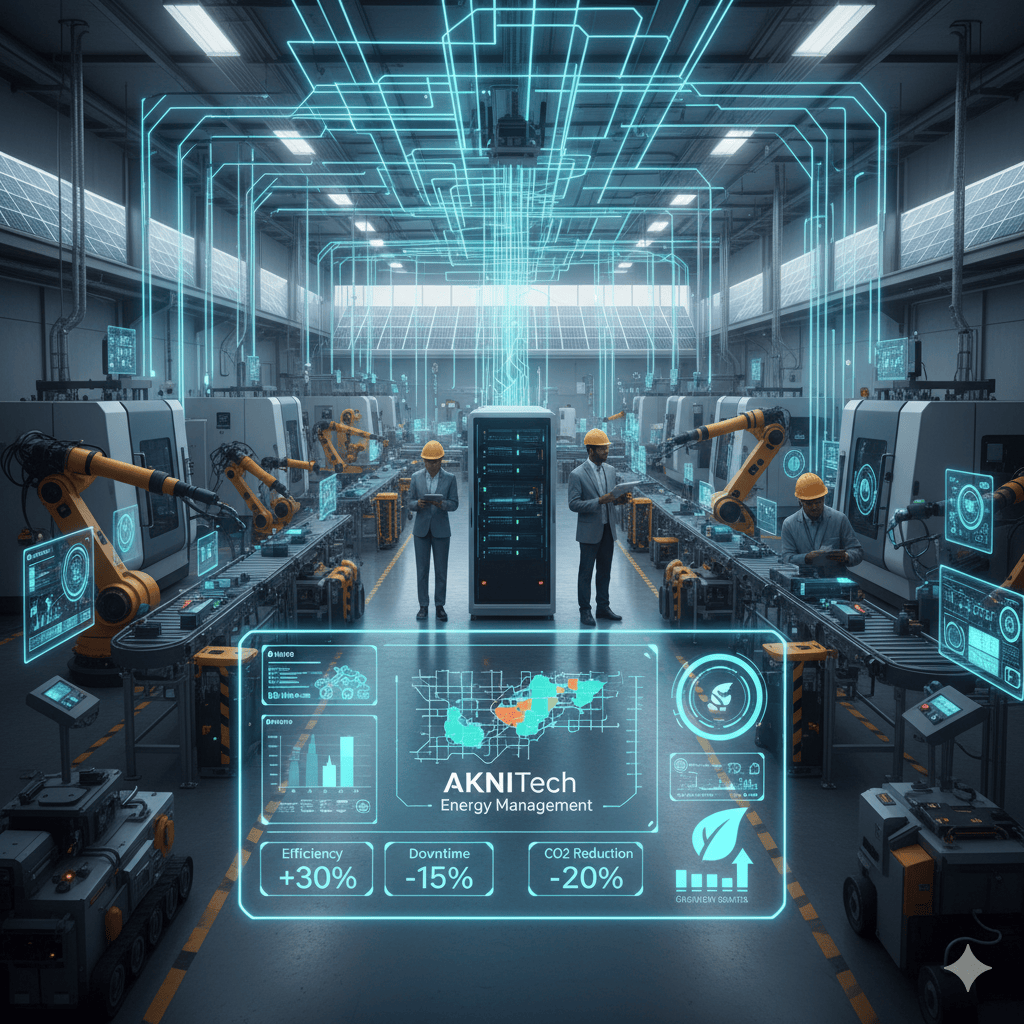

- Increased Productivity By streamlining operations and reducing response times, HMI displays contribute to increased productivity. Operators can manage multiple processes with greater ease, leading to higher output and efficiency in manufacturing.

- User-Friendly Interface Modern HMI systems are designed with user experience in mind. Intuitive interfaces allow operators to navigate functions easily, minimizing training time and enhancing overall productivity. When operators can quickly learn how to use the system, the transition to new technology becomes seamless.

HMI Efficiency in Manufacturing

Manufacturers face numerous challenges, including maintaining quality, reducing waste, and optimizing resource use. HMI displays address these challenges by providing critical insights into manufacturing processes.

For example, a well-implemented HMI system can monitor the efficiency of a production line. By tracking metrics such as cycle times and machine utilization, manufacturers can identify bottlenecks and areas for improvement. This data-driven approach enhances HMI Efficiency, leading to better resource allocation and reduced costs.

Automation Benefits with HMI

The integration of HMI displays in automation systems offers various benefits:

- Scalability: HMI systems can easily be scaled to accommodate changing production needs. As businesses grow, their HMI systems can adapt to manage increased complexity without significant overhauls.

- Safety Enhancements: HMI displays can include safety features, such as alarms and alerts, that notify operators of potential hazards. This proactive approach helps maintain a safer working environment.

- Remote Access: Modern HMI systems often support remote access capabilities. Operators can monitor and control processes from anywhere, increasing flexibility and responsiveness.

- Cost Reduction: By improving efficiency and reducing downtime, HMI technology helps lower operational costs. These savings can be substantial over time, contributing to a healthier bottom line.

Implementing HMI Solutions

To maximize the benefits of HMI technology, businesses must implement these systems thoughtfully. Here are a few best practices:

- Conduct a Needs Assessment: Before implementing HMI systems, evaluate specific needs. Consider factors such as existing equipment, workforce capabilities, and desired outcomes.

- Choose the Right Technology: Select HMI technology that aligns with your operational goals. Consider features like touchscreen interfaces, data logging capabilities, and integration with existing systems.

- Training and Support: Invest in training for operators and staff to ensure they are comfortable using the new technology. Continuous support will help address any challenges that arise post-implementation.

- Regular Updates: Keep HMI software and hardware up to date. Regular updates can enhance performance and security, ensuring the system remains effective over time.

Conclusion

HMI displays are a crucial element in enhancing HMI Efficiency within industrial automation. By providing real-time monitoring, improved communication, and valuable data analysis, these systems drive productivity and efficiency in manufacturing. As industries continue to evolve, the role of HMI technology will only become more significant.

Incorporating HMI systems offers numerous automation benefits, making them an essential investment for businesses seeking to thrive in a competitive landscape. By embracing this technology, manufacturers can achieve higher efficiency and lower costs, positioning themselves for future success.